Tank Weighing Telemetry System – Real-Time Remote Tank Monitoring

Product Overview

The system seamlessly connects with LP710 weighing indicator to capture weight, temperature, and battery voltage. It transmits this data to our secure cloud server, allowing real-time monitoring and management from anywhere

The SCALESTECH Tank Weighing Telemetry System is a next-generation solution for accurate gravimetric tank level measurement, designed for use in industrial inventory control. Whether you’re managing chemicals, fuel, food ingredients, or high-value solids and liquids, this system ensures precise readings, real-time monitoring, and cloud integration for complete visibility from anywhere in Kenya, East Africa, or beyond.

Unlike traditional methods that rely on internal probes or float sensors, our external load-cell system is unaffected by tank shape, internal pressure, viscosity, temperature, or corrosive contents, making it ideal for aggressive, hot, non-flowing, or frozen materials.

Key Features & Benefits

- Gravimetric Accuracy – Weighs from outside the tank; perfect for sensitive or hazardous contents

- Real-Time Cloud Monitoring – Access tank data anytime, anywhere via secure cloud platform

- Data Tracked: Weight, Temperature, Battery Voltage

- Automated Alerts: SMS notifications when thresholds are breached

- Secure Data Transmission: Encrypted for privacy and integrity

- Long Battery Life: Optimized for low power consumption

- Structured Reporting: Generate daily, weekly, and monthly inventory reports

- Multi-Tank Scalability: Monitor multiple tanks across sites

- Device & User Management: Assign users to tanks, manage access control

- Tabular & Graphical Reports: Access structured data and visuals for better decision-making

- Energy Efficiency: Optimized power consumption ensures long battery life.

- Security: Encrypted data transmission protects against unauthorized access.

- Seamless Integration: Compatible with other monitoring systems, including pressure monitoring.

TANK WEIGHING MADE EASY

Do you store your raw materials in tanks? Then you understand how critical it is to monitor your stock levels—from when the tank is filled to when it’s empty. Without proper instruments, relying on estimates can lead to poor planning and unnecessary losses.

While flow meters can help measure fluids during filling or dispensing, their accuracy can be affected by the fluid’s characteristics, such as density. This introduces a higher margin of error if you're not using a precise instrument.

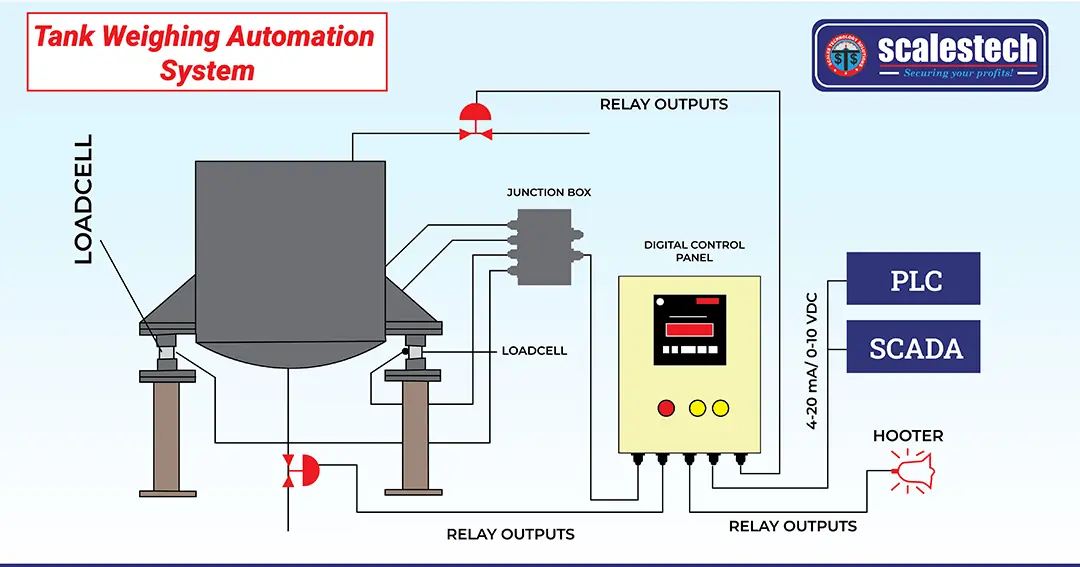

At SCALESTECH, we specialize in the installation of load cells and indicators equipped with telemetry systems that send data to a cloud portal—giving you real-time insights into the actual tank capacity, whether you're using vertical or horizontal tanks.

With our team of experienced experts, we ensure your operations are optimized and your profits are protected!

Real-Time Monitoring & Graphical Insights

Gain instant visibility into your tank's key metrics with a real-time graphical report. This screen provides a clear visual representation of essential parameters, ensuring accurate monitoring and quick decision-making.

Key Features:

- Current Weight – Live weight readings for real-time inventory tracking.

- Current Temperature – Monitor temperature changes to ensure stable conditions.

- Current Voltage – Track battery voltage to prevent power failures.

- Total Readings Overview – View a comprehensive summary of all collected data over time.

This feature enhances operational efficiency by providing data-driven insights for better inventory control, equipment maintenance, and system reliability.

Tabulated Data & Export Feature

Structured Data for Easy Analysis

The Tabulated Data screen provides a detailed, structured view of key tank parameters, making it easier to analyze trends and export data for further processing.

Key Features:

- Organized Data Tables – View neatly arranged records for weight, temperature, and voltage.

- Real-Time & Historical Data – Access both current and past readings for trend analysis.

- Export Functionality – Download data in Excel or CSV format for reports and external analysis.

- With this feature, users can efficiently track performance, generate reports, and integrate data into their operational workflows.

Device Management

Effortless User & Device Administration

The Device Management screen allows for seamless user onboarding and device configuration, ensuring secure and efficient system management.

Key Features:

- User Management – Add new users by capturing essential details for secure access.

- Device Assignment – Link users to specific devices for controlled monitoring and management.

- User & Device Overview – View and manage all registered users and their assigned devices in one place.

This feature ensures secure access control, efficient device allocation, and better system oversight, making it easier to manage multiple users and devices across different locations

SMS Notifications & Delivery Status

Real-Time SMS Alerts & Delivery Tracking

The SMS Notifications screen provides a detailed log of all alerts and messages sent by the system, ensuring timely communication and efficient issue tracking.

Key Features:

- Message Details – View the SMS body to understand the exact alert sent.

- Timestamp Tracking – Know the exact time each SMS was sent for audit and verification.

- Delivery Status – Instantly see whether the message was successfully delivered or failed, enabling quick troubleshooting.

This feature ensures that critical notifications reach users on time, helping them take immediate action on tank status updates, low stock alerts, or device issue

Tank Consumption Monitoring

Stay in control of your tank’s usage with our real-time consumption tracking dashboard. This feature provides detailed insights into your tank’s status, weight, and consumption patterns, helping you manage stock efficiently and avoid unexpected shortages.

Key Features:

- Detailed Tank Status – View the current weight of the tank in kilograms for accurate monitoring.

- Daily, Weekly & Monthly Consumption Tracking – Analyze usage trends over time to plan for refills and optimize stock levels.

- Consumption Reports – Generate and download reports on tank usage for better decision-making.

- Low Stock Alerts – Get instant notifications when stock levels drop below set thresholds, preventing operational disruptions. By providing historical data and real-time monitoring, this tool helps users make informed decisions on inventory management, refilling schedules, and cost optimization

Use Cases & Applications

Scalestech’s telemetry tank weighing system is trusted in:

- Chemical Plants: Corrosive or temperature-sensitive inventory tracking

- Fuel Storage & LPG Monitoring: Bulk fuel and gas stock control

- Beverage & Food Plants: Weighing tanks for dairy, juice, syrups, and liquids

- Construction Industry: Cement and additives weighing

- Pharmaceutical Plants: Controlled material measurement

- Fire & Safety Industries: Monitoring extinguisher tanks or pressurized containers

- Water Treatment & Environmental Systems

- Manufacturing Plants: Raw materials, adhesives, and paint storage

- Distribution Warehouses: Centralized multi-tank tracking

.webp?unique=13d76c0)

.webp?unique=13d76c0)