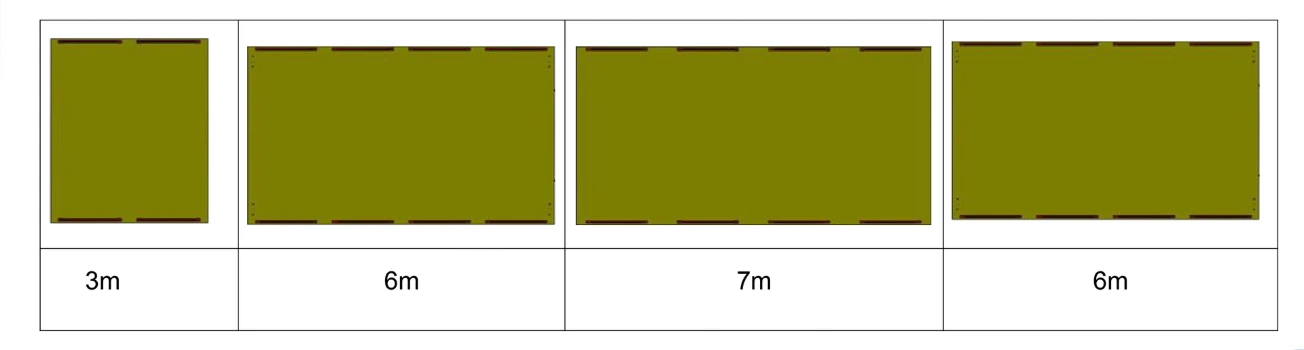

Scale Dimensions & Layout

| Category | Item | Details |

|---|---|---|

| Foundation | Total Length | 125 + 2800 + 200 + 5800 + 200 + 6800 + 200 + 5800 + 125 = 22050 mm |

| Scale Size | Platform Length | 3000 + 6000 + 7000 + 6000 = 22000 mm |

| Plate | Material | 12 mm Checker Plate |

| Load Cell Configuration | Long Direction Center Distance | 2800 mm, 5800 mm, 6800 mm, 5800 mm |

| Wide Direction Center Distance | 2900 mm | |

| Beam Height | 320 mm × 8 pieces | |

| Section Lengths | First Section | 3 m |

| Second Section | 6 m | |

| Third Section | 7 m | |

| Fourth Section | 6 m |

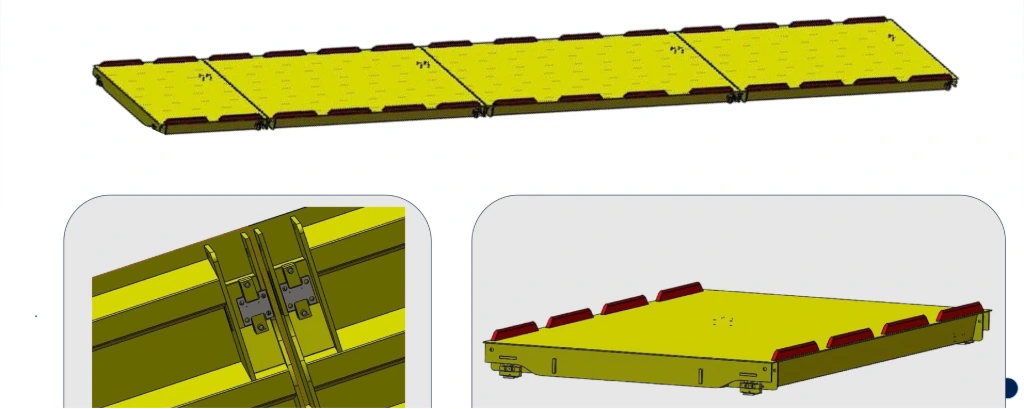

Overall View

The truck scale consists of four independent sections that work together as a complete weighing system. Each section is designed to handle specific portions of the truck weight while maintaining accuracy across the entire platform.

Working Principle

Independent Weighing System

The scales operate independently of each other while functioning as a complete system.

Vertical & Horizontal Limits

Special consideration for scale body shifting to maintain accuracy.

Longitudinal Limitation

Limit screws at the ends of first (3m) and fourth (6m) sections with 2-3cm space reserved.

Lateral Limitation System

The lateral/lateral limit is controlled by an additional limit plate on the end plate of the scale body. This prevents unwanted side-to-side movement while allowing for proper weight distribution

Load Cell - KELI 30T

Load Cell Features:

* Capacity: 30T

* Steel ball loading, strong restoration ability

* Easy complete installation, high weighing accuracy

* OIML C3 certificate

* Alloy Steel

Technical Features

| Parameter | Specification | Parameter | Specification |

|---|---|---|---|

| Rated Load | 5, 10, 15, 20, 25, 30, 40, 50 t | Operating Temp Range | −30 ~ +70°C |

| Sensitivity | 2.0 ± 0.002 mV/V | Safe Load Limit | 150%, 120% (40–50 t) F.S |

| Total Error | C2 | Overload Limit | 300%, 200% (40–50 t) F.S |

| Creep (30 min) | ±0.02% F.S | Recommended Excitation | 10–12 V DC |

| Zero Balance | ±1% F.S | Maximum Excitation | 15 V DC |

| TCO | ±0.02% F.S / 10°C | Protection Class | IP67 (5 t), IP68 (10–50 t) |

| TC Span | ±0.02% F.S / 10°C | Construction | Alloy Steel |

| Input Resistance | 750 ± 10 Ω | Cable Length | L: 5.2 m (5 t), 8 m (10 t), 10 m (15 t), 10/12 m (20 t) |

| Output Resistance | 702 ± 3 Ω, 702 ± 5 Ω (L ≥ 15 m) | Cable Length (cont.) | 12/15 m (25 t), 12/16 m (30 t), 16 m (40–50 t) |

| Insulation Resistance | ≥ 5000 MΩ | Cable Diameter | Ø 6 mm |

INDICATOR - ZM 510

User-centred design

Enclosures

Constructed for use in the office, dusty, wet or high pressure, heavy washdown and outdoor environments, the ZM510 is IP69K certified and enclosed in 304 brushed stainless steel. Designed for long service in extreme conditions, including corrosive environments and frequent, heavy washdown, the ZM510 adapts to desk, wall or column mount applications

Keypads

With metal domed tactile keys and audio contact confirmation, the ZM510’s large QWERTY keypad makes it flexible for use across all applications. Five programmable keys allow for specific weighing tasks to be assigned to the indicator, allowing weighing operations to be carried out quickly and effectively. The ZM510 can also be connected to a USB keyboard

Dot matrix graphical display

High contrast, Improved Super Twisted Nematic graphic display gives the ZM510 excellent visibility and colour contrast. With its wide viewing angles, the ultra bright green and black dot graphic display is easily visible in extreme working conditions and

The ZM510 is a high performance, multi-function indicator, flexible enough to adapt to complex weighing tasks. Programmable and highly connective, the ZM510 displays, analyses, stores, and transmits data across devices, offering an end-to-end, personalised weighing solution.

Remote Display Unit

The weight of the axles can be shown on large external displays with 120 mm high red LED digits making the information visible to the driver immediately. An external display can also show the gross weight of the vehicle.The large displays are fully waterproof. The displays show zero when the platform is idle and when overloads are detected, the appropriate display will flash, showing which sets of axles are causing the problem